MDF Cabinet Door Construction Techniques

![]()

Constructing MDF cabinet doors offers a blend of affordability and design flexibility. MDF’s smooth surface and machinability make it ideal for various styles, from simple slab doors to intricate raised panels. This section details the process of building MDF cabinet doors, covering basic construction, advanced techniques for raised panels, and a step-by-step guide for creating Shaker-style doors.

Basic MDF Cabinet Door Construction

Building a basic MDF cabinet door involves several key steps: cutting the door to size, shaping edges, and applying edge banding for a professional finish. The following table Artikels the process:

| Step | Material | Tool | Description |

|---|---|---|---|

| 1. Cut to Size | MDF sheet | Circular saw, Table saw, or Panel saw | Accurately cut the MDF sheet to the desired door dimensions, ensuring square cuts for a perfect fit. Use a measuring tape and square for precise measurements. |

| 2. Shape Edges (Optional) | MDF sheet | Router with appropriate bits, Hand plane | If desired, create a profile on the edges of the door using a router with a suitable profile bit. Alternatively, a hand plane can be used for a more rustic look. |

| 3. Apply Edge Banding | Edge banding (PVC or Melamine), Wood Glue, Iron | Iron, Utility knife, Sandpaper | Apply edge banding to the exposed edges of the door using wood glue and an iron to melt the adhesive. Trim excess banding with a utility knife and sand smooth. |

| 4. Sanding | Sandpaper (various grits) | Sandpaper, sanding block | Sand the entire surface of the door to remove any imperfections or rough edges, progressing through finer grits for a smooth finish. |

| 5. Finishing (Optional) | Primer, Paint, or Stain | Paintbrushes, rollers, or spray gun | Apply a primer followed by paint or stain to achieve the desired finish. Multiple coats may be needed for optimal coverage and durability. |

Raised Panel MDF Cabinet Door Construction Methods

Several methods exist for creating raised panels in MDF cabinet doors. Each offers unique advantages and disadvantages:

Making mdf cabinet doors – The choice of method depends on factors such as available tools, desired level of detail, and budget.

- Router Method: Uses a router and various bits to create the raised panel profile. This method offers precision and detail but requires experience with a router. Advantages include precise control and intricate designs; disadvantages include the need for specialized tools and expertise.

- CNC Machining: Employs a computer numerical control machine for precise and efficient panel creation. Offers high precision and speed but requires access to a CNC machine. Advantages include high speed and accuracy; disadvantages include high initial investment and reliance on specialized equipment.

- Hand-Cut Method: A traditional approach involving hand tools such as chisels and planes. This method is time-consuming but allows for unique, handcrafted details. Advantages include a unique, handcrafted look; disadvantages include high time investment and requires skill.

Shaker-Style MDF Cabinet Door Construction

Creating a Shaker-style MDF door involves a straightforward process. The style is characterized by its simple, flat-panel design with a recessed frame.

This step-by-step guide provides a detailed illustration of the process.

- Cut the Frame and Panel: First, cut the MDF into pieces for the frame (four rails and two stiles) and the central panel. Imagine a rectangle with a smaller rectangle inside it, leaving a frame around the inner rectangle. The outer rectangle is your frame, the inner rectangle is your panel.

- Assemble the Frame: Use wood glue and clamps to join the frame pieces, ensuring square corners. A jig or miter box can aid in achieving accurate 90-degree angles. Visualize this as carefully joining the four sides of the outer rectangle.

- Insert the Panel: Once the glue is dry, carefully insert the central panel into the frame. The panel should fit snugly but not be forced. Think of it as carefully sliding the inner rectangle into the assembled outer rectangle.

- Secure the Panel (Optional): For added strength, you can use small brads or pocket screws to secure the panel to the frame from the back. This step adds stability to the structure. Imagine small nails or screws holding the inner and outer rectangles together from the backside.

- Sand and Finish: Sand the entire door smooth, paying attention to any seams or edges. Apply primer and paint or stain to complete the door. This final step refines the surface for a clean, polished look.

Finishing and Refinishing MDF Cabinet Doors

_Page_2.png)

MDF cabinet doors offer a smooth, consistent surface ideal for a variety of finishes, allowing for significant customization in kitchen and bathroom designs. Proper finishing techniques are crucial for achieving a durable and aesthetically pleasing result, while refinishing addresses the need to update or repair existing doors. Understanding the different methods available ensures the longevity and beauty of your cabinetry.

Painting MDF Cabinet Doors, Making mdf cabinet doors

Careful preparation is paramount for a successful paint job on MDF. The smooth surface of MDF can be deceiving; proper priming and multiple coats of paint are necessary to achieve a professional finish that resists chipping and scratches. The following steps Artikel the key aspects of painting MDF cabinet doors.

- Surface Preparation: Begin by thoroughly cleaning the doors with a degreaser to remove any dirt, grease, or dust. Lightly sand the surface with fine-grit sandpaper (220-grit) to create a slightly textured surface for better paint adhesion. Fill any imperfections with wood filler, allowing it to dry completely and sanding smooth before proceeding.

- Primer Application: Apply a high-quality primer specifically designed for MDF. This will seal the pores of the MDF, preventing the wood from absorbing the paint unevenly and creating a smoother, more durable finish. Allow the primer to dry completely according to the manufacturer’s instructions.

- Topcoat Selection: Choose a high-quality paint suitable for cabinetry, such as acrylic-alkyd or acrylic-urethane. These paints offer excellent durability and resistance to scratches and moisture. Apply two to three thin coats, allowing each coat to dry completely before applying the next. Lightly sand between coats with fine-grit sandpaper to ensure a smooth finish.

Comparison of Finishes for MDF Cabinet Doors

Various finishes offer distinct advantages and disadvantages in terms of durability, appearance, and application. Selecting the appropriate finish depends on the desired aesthetic and the level of durability required.

| Finish Type | Durability | Appearance | Application Method |

|---|---|---|---|

| Acrylic Lacquer | High; resistant to scratches and moisture | Smooth, glossy to semi-gloss; can be tinted to various colors | Spraying or brushing |

| Oil-Based Polyurethane | High; durable and water-resistant | Durable, can range from satin to high gloss; ambering may occur over time | Brushing or spraying |

| Water-Based Polyurethane | Good; durable and water-resistant, less odor than oil-based | Various sheens available; generally less ambering than oil-based | Brushing or spraying |

| Stain | Moderate; requires a topcoat for protection | Highlights the wood grain (although MDF doesn’t have a natural grain, it can create a textured look with the right application); wide variety of colors available | Brushing or wiping |

Refinishing Existing MDF Cabinet Doors

Refinishing MDF cabinet doors involves removing the old finish, addressing any damage, and applying a new finish. This process can significantly improve the appearance and longevity of your cabinets.

- Removing the Old Finish: If the existing finish is paint, use a paint scraper or chemical stripper to remove it. Sand the surface smooth after removing the old finish. If the existing finish is a lacquer or polyurethane, sanding with progressively finer grits of sandpaper is usually sufficient. Always wear appropriate safety gear, including a respirator and gloves.

- Repairing Damage: Fill any dents, scratches, or chips with wood filler, allowing it to dry completely and sanding smooth. For more significant damage, consider replacing the door entirely.

- Applying a New Finish: Clean the surface thoroughly to remove all sanding dust. Apply a primer designed for MDF, followed by the chosen topcoat (paint, stain, or polyurethane). Follow the manufacturer’s instructions for drying times and the number of coats needed. Lightly sand between coats for a smooth finish.

Design and Customization of MDF Cabinet Doors: Making Mdf Cabinet Doors

.webp)

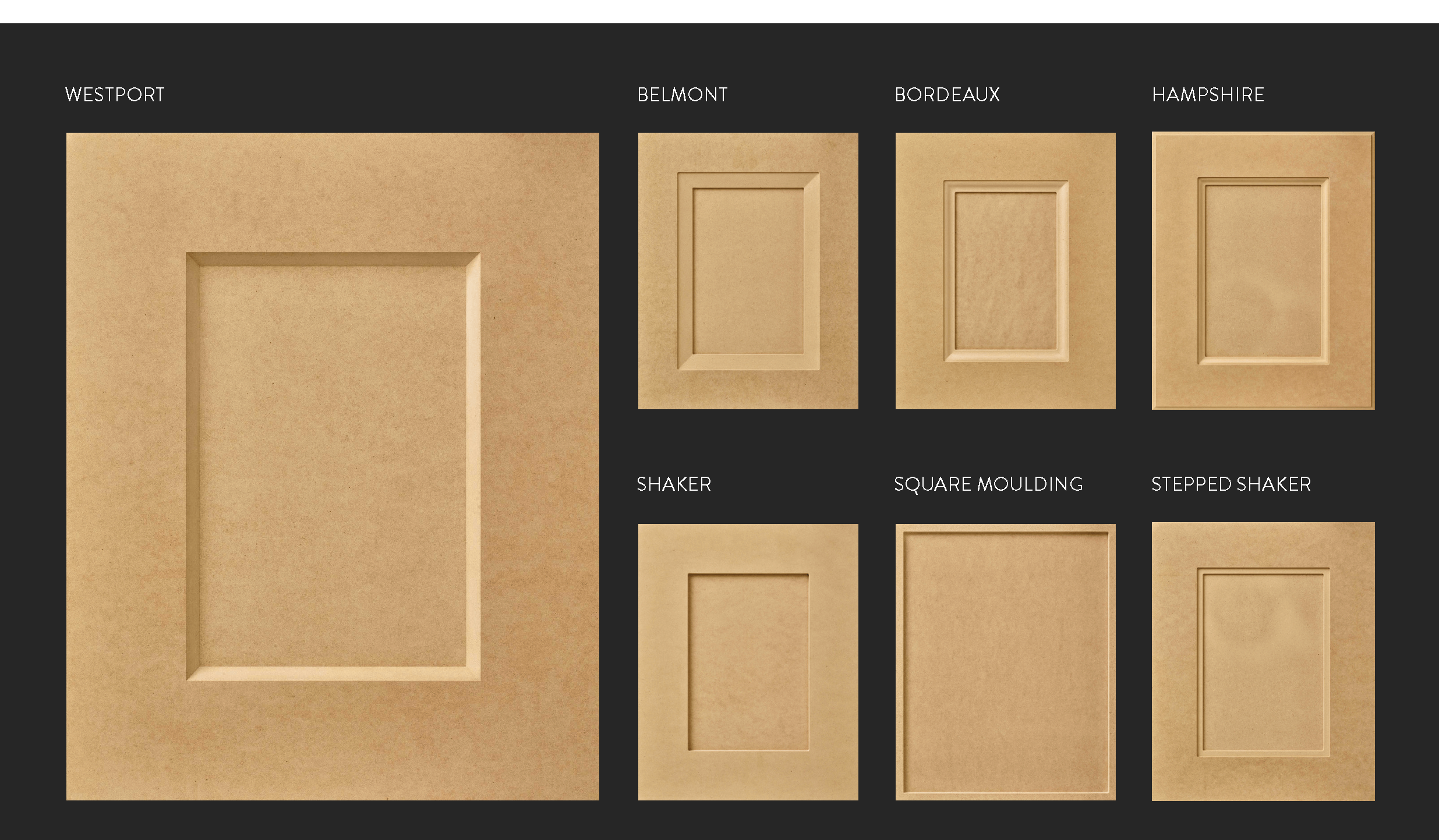

MDF (medium-density fiberboard) offers incredible versatility for cabinet door design. Its smooth surface and ability to hold detail make it an ideal substrate for a wide range of styles and customizations, from sleek modern designs to ornate traditional pieces. Let’s explore some design concepts and decorative techniques to unlock the full potential of MDF cabinet doors.

Design Concepts for Different Styles of MDF Cabinet Doors

The inherent properties of MDF allow for a broad spectrum of design aesthetics. The choice of materials, hardware, and finishing techniques significantly impacts the overall style.

Modern Style

Imagine clean lines, minimalist hardware, and a sophisticated color palette. For a modern MDF cabinet door, consider a flat-panel design with a high-gloss lacquer finish in a bold color like charcoal gray or deep navy. Sleek, brushed nickel bar pulls or recessed handles would complement the minimalist aesthetic. The smooth, unadorned surface emphasizes the clean lines of the design. The focus is on simplicity and functionality.

Traditional Style

Traditional style evokes a sense of classic elegance and craftsmanship. For this look, raised panel doors with detailed molding are ideal. Consider using a rich, warm stain like cherry or walnut to enhance the wood grain effect. Ornate brass knobs or cup pulls would complete the look, adding a touch of vintage charm. A slightly distressed finish could add to the antique feel, mimicking the patina of aged wood.

Rustic Style

Rustic style emphasizes natural textures and a sense of warmth. For rustic MDF cabinet doors, consider a distressed paint finish, perhaps in a muted color like creamy white or sage green. The paint could be applied unevenly to highlight the texture of the MDF. Simple, wrought-iron hardware would complement the rustic feel. A wire-brushed finish could further enhance the texture, adding a touch of weathered elegance. Consider incorporating reclaimed wood accents for an added layer of authenticity.

Incorporating Decorative Elements into MDF Cabinet Doors

Adding decorative elements elevates MDF cabinet doors from simple functional pieces to unique design statements. Inlays and carvings are just two of the many techniques available.

The following sections detail two methods for incorporating decorative elements into your MDF cabinet doors. Careful planning and precise execution are key to achieving professional results.

Inlay Technique

This technique involves inserting contrasting materials into pre-cut grooves in the MDF.

- Design and Cut: Create a design using stencils or freehand. Use a router with a suitable bit to precisely cut the grooves according to your design. Ensure the depth of the groove is consistent with the thickness of the inlay material.

- Material Selection: Choose inlay materials that complement your overall design. Options include wood veneers, colored resins, or even metallic accents. Ensure the chosen material is compatible with the MDF and adhesive.

- Adhesive Application: Apply a strong adhesive, such as wood glue, to both the inlay material and the grooves in the MDF. Ensure complete coverage for a secure bond.

- Inlay Placement: Carefully insert the inlay material into the grooves, ensuring it sits flush with the MDF surface. Use clamps or weights to hold it in place until the adhesive sets completely.

- Finishing: Once the adhesive is dry, sand the inlay flush with the MDF surface. Apply your chosen finish to complete the project.

Carving Technique

Carving adds intricate detail and visual interest.

- Design Transfer: Transfer your design onto the MDF surface using carbon paper or a projector. Choose a design appropriate for your skill level and the tools available.

- Tool Selection: Select appropriate carving tools, such as chisels, gouges, or a Dremel tool with carving bits. Sharp tools are crucial for clean cuts and precise detail.

- Carving Process: Begin by outlining the design with shallow cuts. Gradually deepen the cuts to create the desired depth and detail. Work carefully and methodically, removing small amounts of material at a time.

- Sanding and Finishing: Once the carving is complete, sand the surface smooth, paying attention to the details. Apply a finish that complements the carved design and protects the MDF.